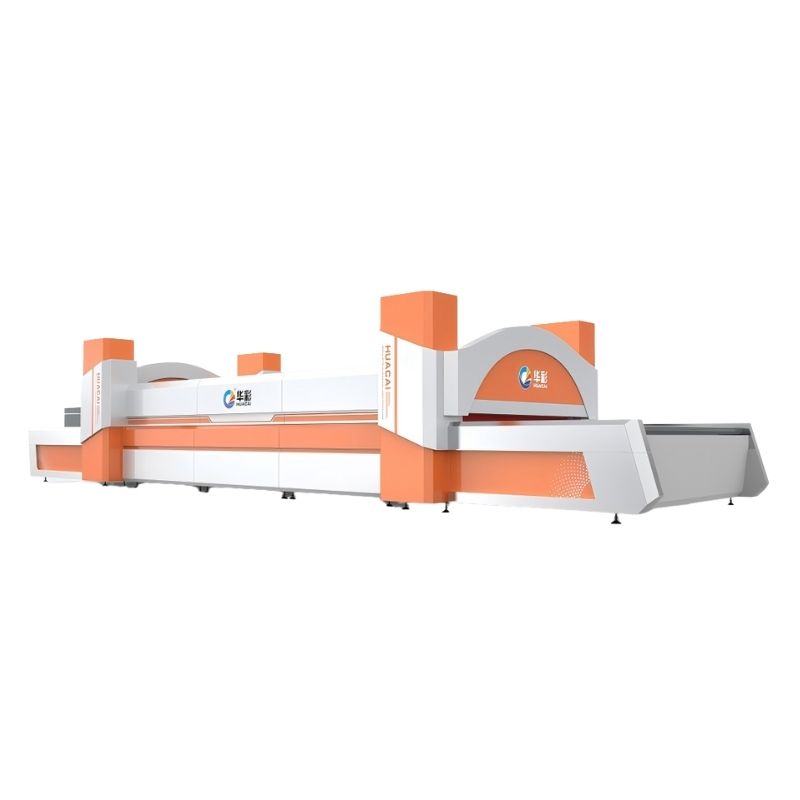

Standard Heated Roller Press

The standard glass heated roller press is comprised of the electrical cabinet and loading, pre-heating, pre-pressing, 1st heating, 2nd heating, roll pressing and unloading section.

Technical Characteristics

The standard glass heated roller press is comprised of the electrical cabinet and loading, pre-heating, pre-pressing, 1st heating, 2nd heating, roll pressing and unloading section.

After undergoing pre-heating, pre-pressing, heating and pressing, two or more layers of glasses and a PVB interlayer are bonded together to form an initial laminated glass, which then passes through a series of imported high-temperature-resistant rubber rollers to expel any air pockets and strengthen the bonding performance.

Heating element is the quartz heating pipe.

Specifications

Glass width (mm): 2500

Glass thickness(mm): 6~80 (digital display)

Min. glass size(mm): 400×400

Power (KW): 104.4

Conveying speed(m/min): 0.5~2.5

Air pressure (MPa): 0.6~0.8

Overall Dimension(mm): 9580×3500×1700

Single-Fan Cleaning Machine

Single-Fan Cleaning Machine  Glass Cleaning Machine

Glass Cleaning Machine  Laminated Glass Pre-pressing

Laminated Glass Pre-pressing  Heated Roller Press with Indep...

Heated Roller Press with Indep...  Curved and Flat Laminated Glas...

Curved and Flat Laminated Glas...  Heated Roller Press with Force...

Heated Roller Press with Force...  Standard Heated Roller Press

Standard Heated Roller Press  Glass Laminating Autoclave

Glass Laminating Autoclave  Glass Production Line

Glass Production Line  Flat laminated glass line

Flat laminated glass line  Fire Resistant Glass Laminatin...

Fire Resistant Glass Laminatin...  Horizontal Glass Washing Machi...

Horizontal Glass Washing Machi...  Heat Soaking Oven

Heat Soaking Oven  Strip Laminating Machine

Strip Laminating Machine  Homogenizing Furnace

Homogenizing Furnace  Fire-Resistant Curing Oven wit...

Fire-Resistant Curing Oven wit...  Semi-auto Glass Vacuum Lifter

Semi-auto Glass Vacuum Lifter  Automatic Laminated Glass PVB ...

Automatic Laminated Glass PVB ...