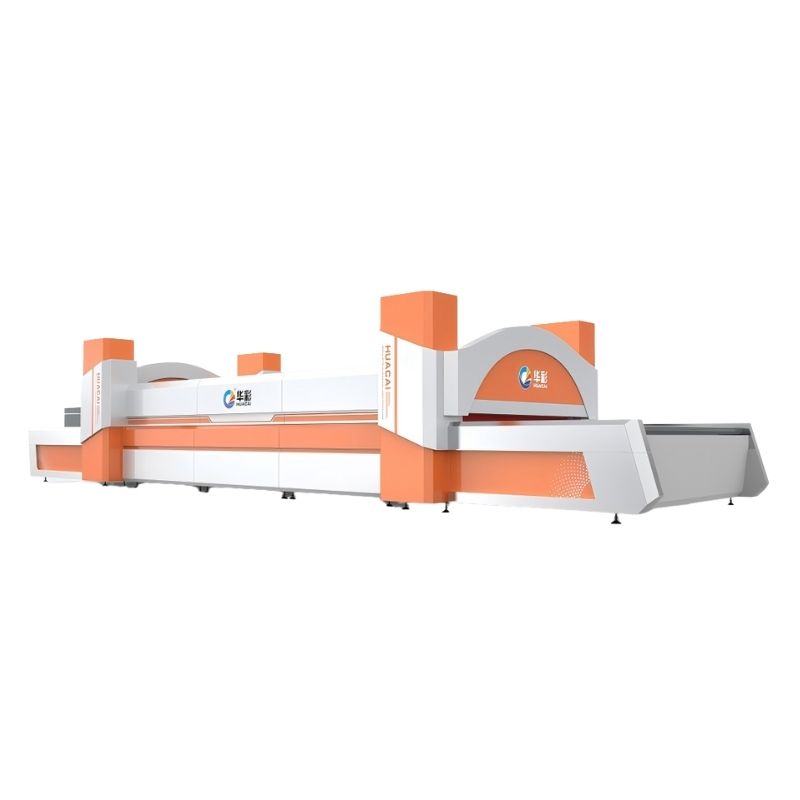

Dual-Fan Energy-Saving Cleaning Machine

Huacai Glass Cleaning Machine: Custom Solutions for Superior Glass Processing

Huacai offers custom glass cleaning machines with a width range of 1200-3500mm, tailored to meet diverse production needs. We maintain inventory of standard models—QX1600, QX1800, QX2000, QX2500, and QX3000—ensuring fast delivery and consistent, reliable quality.

Model B: Designed for regular flat glass.

Models C, D, E: Specialized for Low-E glass.

Choose the optimal glass washing system based on your glass type, glass size, and cleaning/drying speed to enhance glass manufacturing efficiency and improve laminated glass quality.

Technical Specifications

| Parameter | Details |

|---|---|

| Maximum Glass Width | 1200mm - 3500mm |

| Minimum Glass Size | 300×300mm |

| Glass Thickness | 3~25 mm |

| Conveying Speed | Up to 15 m/min |

| Power Supply | 380V 50HZ (customizable to your local power standard) |

| Total Power | Varies by machine model |

Machine Features

1. Robust Structure & Durable Components

The machine frame is welded from high-quality profiles and coated with top-grade paint for corrosion resistance and long service life.

Conveyor rollers are available in φ60mm, φ85mm, and 100mm full-vulcanized rubber options, ensuring high durability and stable glass conveyance.

2. Advanced Pre-Washing & Rust-Proof Design

The loading and pre-rinsing section is equipped with stainless steel water trays and spray hoses. All water-contacting parts are made of stainless steel to prevent rust.

Rubber conveyor rollers pre-rinse the glass from the bottom, preventing contaminants from entering the water tank and avoiding scratches on the glass surface and rollers.

3. Efficient Cleaning & Easy Maintenance

The washing and drying section uses high-strength lifting screws; the upper part of the section can be electrically lifted up and down for convenient operation and maintenance.

Three pairs of brush rollers effectively clean float glass, Low-E glass, and coated glass, ensuring thorough dirt removal.

4. Space-Saving & Low-Noise Drying System

The drying section features a compact design with low noise and high production capacity. Fans are installed above the drying section to reduce floor space occupancy.

The fan box inlet is equipped with a fine filter screen and surrounded by sound-absorbing materials, reducing operating noise without compromising air-blowing performance.

Two pairs of air knives are manufactured using Italian stainless steel processing technology, providing unparalleled drying performance compared to traditional drying methods.

5. Stable Transmission & Water-Saving System

The transmission mechanism is driven by bevel gears, ensuring high stability and durability during long-term operation.

The intermediate water recycling system controls water supply, saves water resources, and lowers production costs.

The water tank is made of high-quality stainless steel panels. The connector with the water pump is equipped with a "quick plug," allowing easy removal of the tank for cleaning.

6. Intuitive Electronic Control System

Motors, blowers, water pumps, glass conveyors, lighting, and lifting devices are controlled by independent buttons for precise operation.

The horizontal glass cleaning machine features a rational design, sleek appearance, and user-friendly operation, with a VFD (Variable Frequency Drive) main drive and digital display for glass thickness.

Lifting height is controlled by a high-precision TOKY encoder and intelligent digital instrument, ensuring accurate adjustment.

7. Hygienic & Versatile Water Supply

The machine cover is made of stainless steel, ensuring high durability and easy cleaning.

The self-circulating water supply system can use tap water or deionized water (deionization equipment is not included in the flat glass laminating line).

Important Note for Low-E Glass Cleaning

Due to the inconsistent quality of Low-E glass, special attention must be paid to the daily maintenance of the glass cleaning machine and the specific cleaning methods for Low-E glass. It is recommended to clean Low-E glass with deionized water or pure water, which must meet the following standards:

d- < 3mg/l

Conductivity < 20μs/cm

pH: 6-8

Single-Fan Cleaning Machine

Single-Fan Cleaning Machine  Glass Cleaning Machine

Glass Cleaning Machine  Laminated Glass Pre-pressing

Laminated Glass Pre-pressing  Heated Roller Press with Indep...

Heated Roller Press with Indep...  Curved and Flat Laminated Glas...

Curved and Flat Laminated Glas...  Heated Roller Press with Force...

Heated Roller Press with Force...  Standard Heated Roller Press

Standard Heated Roller Press  Glass Laminating Autoclave

Glass Laminating Autoclave  Glass Production Line

Glass Production Line  Flat laminated glass line

Flat laminated glass line  Fire Resistant Glass Laminatin...

Fire Resistant Glass Laminatin...  Horizontal Glass Washing Machi...

Horizontal Glass Washing Machi...  Heat Soaking Oven

Heat Soaking Oven  Strip Laminating Machine

Strip Laminating Machine  Homogenizing Furnace

Homogenizing Furnace  Fire-Resistant Curing Oven wit...

Fire-Resistant Curing Oven wit...  Semi-auto Glass Vacuum Lifter

Semi-auto Glass Vacuum Lifter  Automatic Laminated Glass PVB ...

Automatic Laminated Glass PVB ...